Learn From Experience

Improve your entire manufacturing process by constantly identifying inefficiencies in real-time. Our Generative Manufacturing Platform (GMP) is built on over 60 years of experience designing and implementing sophisticated manufacturing software solutions.

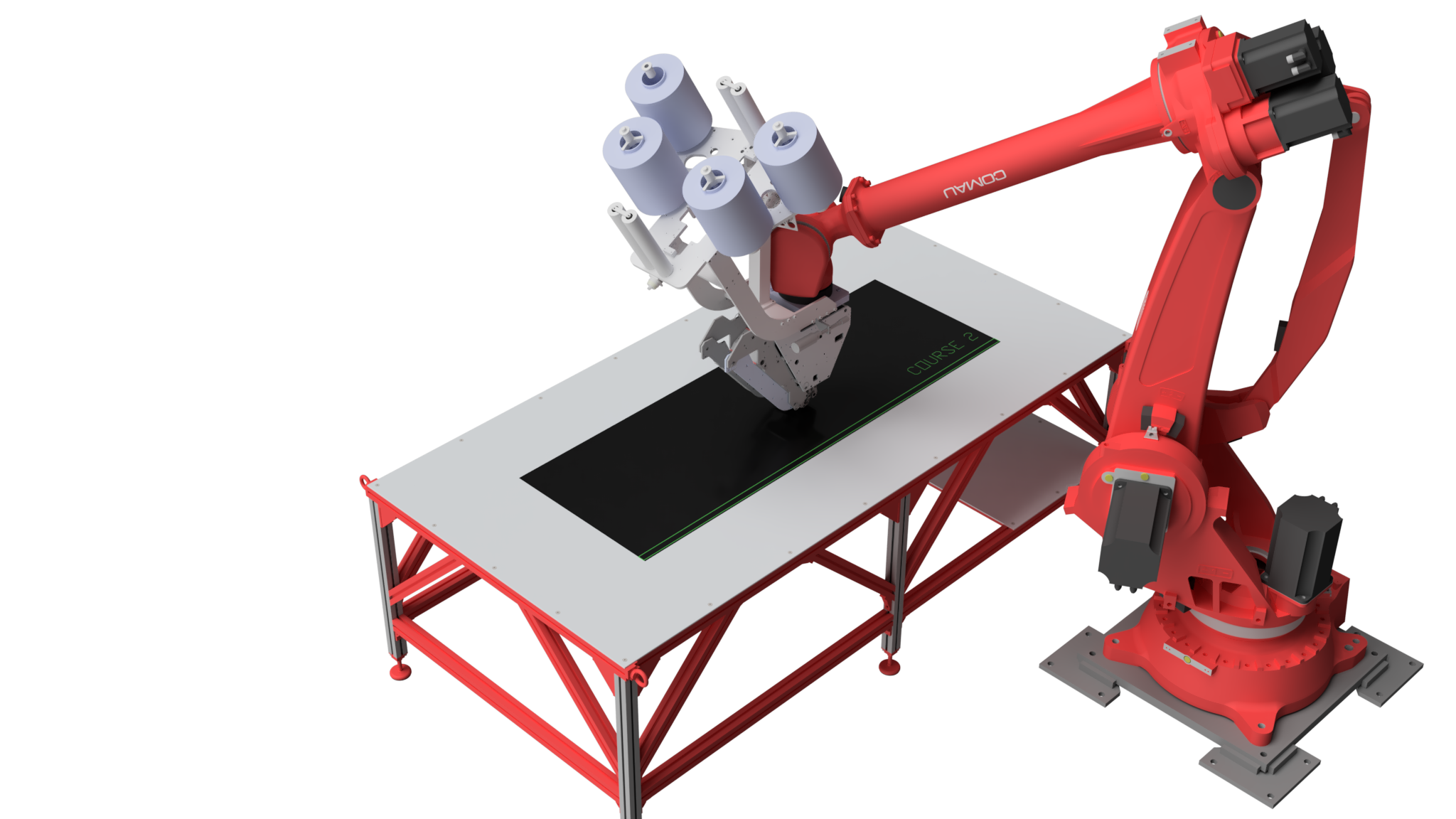

GMP leverages innovative technologies in Genetic Algorithms, Machine Learning, IIOT and A.I. to optimize manufacturing processes such as scheduling, material consumption, NC programming, tooling, machine cycles, etc… GMP is also an open architecture that seamlessly integrates with other applications thus allowing digital information to be shared and leveraged across other manufacturing disciplines in the organization.

FOLLOW THE DIGITAL THREAD

Connect the islands, breakdown silos and share real-time information in the manufacturing processes to make better business decisions.

All Manufacturers Have Similar Needs. The need to align what is sold, how to make it, how to schedule shop floor resources and how much it costs to make. This usually involves CRM, ERP, CAD, CAM and Production, but often these groups never share information in order for management to know “did we make it at the projected costs?”

Sharing digital information among these disciplines will help answer this question and ultimately improve profitability. However, wouldn’t it be nice if you could take all this information to identify areas that could be improved and do it automatically in real-time. Wouldn’t it be even better if these improvements were being made on an ongoing basis, so improvements were being made on improvements and so on and again, automatically! We call this “Generative Manufacturing” and it leverages Genetic Algorithms, Machine Learning and AI to help make improvements to your manufacturing process every time you run production.

WHAT IS YOUR ADVANCED MANUFACTURING PROCESS?

Our vision is focused on a closed loop digital manufacturing strategy for orders, material and manufacturing process optimization in the aerospace, energy, transportation, and automotive industries.

Magestic Technologies is a world leader in providing best in class manufacturing software solutions.The founders have attained an international reputation as a “go to” for manufacturers who require complex integrated manufacturing solutions for advanced composites, sheet metal fabrication, heavy plate cutting, honeycomb interior fabrication, leather hide cutting, as well as CAM applications such as milling and turning, whether for material yield improvements, cutting optimization or seamless ERP integration, Magestic Technologies has the experience and expertise to get the job done.

WE’RE WITH YOU EVERY STEP OF THE WAY

We not only provide best in class solutions, we provide the best in class service and support. Our team provides on-site or off-site consulting, design, implementation, integration, technical support and training services.

We’ve learned a lot in our 60 years in this business, and that is consulting, implementation, training and technical support are critical to the success of any project. We want to earn your business by working with your team to design, configure and implement the best possible solution and then provide the critical training and technical support to ensure a successful completion. Our goal is to do such a great job we become one of your strategic partners and you entrust us with more opportunities as you grow and evolve.

WHAT WOULD YOU LIKE YOUR MANUFACTURING SOLUTION TO INCLUDE?

ERP Integration to Manufacturing

Seamless bi-directional information sharing

Optimized Order Scheduling

Optimized shop floor orders based on real-time machine availability and cycle times.

Optimized Material Inventory Management

GMP optimizes the use of raw stock and remnants. GMP considers the various sizes of a given material in inventory, the cost of each size of that material and how you want to use your remnants.

Generative Manufacturing Optimization

Use genetic algorithms to continually improve your processes. The genetic algorithms are a major function in our Generative Manufacturing Platform (GMP) and operate automatically and transparently. Using a representative seed/example and the constraints of a given process, our Generative ManufacturingPlatform will continue to find improvements to a given process each time that process is initiated.

Collaboration Between Design and Manufacturing Engineering

Considers a given manufacturing process at the design stage without having to know anything about manufacturing, thus potentially improving cycle times, tooling and production rates.

Material Optimization

Our Generative Manufacturing Platform utilizes GAs to improve material efficiencies.

IIOT Integration

Digitally collect real-time machine production data and provide it back upstream to better align Quoting, ERP and Production

READY TO KEEP LEARNING? WANT A FREE BROCHURE?

JOIN OUR MAILING LIST FOR UPDATES, NEWS AND MORE!